pulseCHECKER’s Alerts, Sensors, and Reports Work for ANY Industry

The High Cost of “Business as Usual”

Manual monitoring isn’t just inefficient—it’s a liability. Imagine missing a critical alert because your team was buried in spreadsheets, or wasting $20,000 on a sensory system that requires months of IT integration. For industries relying on guesswork, every unmonitored machine is a ticking time bomb….a 50K repair here, a compliance fine there, until margins vanish entirely.

Manufacturing: Ignored 5% CNC vibration spike → $200K downtime.

Healthcare: Unmonitored hospital generator fails mid-storm → patient safety risk.

Retail: Freezer door left open overnight → $10K in spoiled goods.

Transportation: Delivery truck engine overheats → stranded shipment, $5K penalty.

Agriculture: Irrigation pump leak undetected → 20% water waste, crop loss.

How pulseCHECKER Transforms ANY Operation

pulseCHECKER’s platform isn’t tied to a single industry—it’s a universal toolkit for predictive insights, automated workflows, and risk mitigation. Whether you’re managing HVAC systems, pipelines, or MRI machines, here’s how it works:

1. Alerts That Act Like a 24/7 Safety Net

SMS/email alerts notify the right person when metrics stray from norms (e.g., “Walk-in freezer door left open → Close it NOW”).

Escalate critical alerts to managers or automate shutdowns for dangerous conditions.

Audit-ready logs track every alert, response, and resolution.

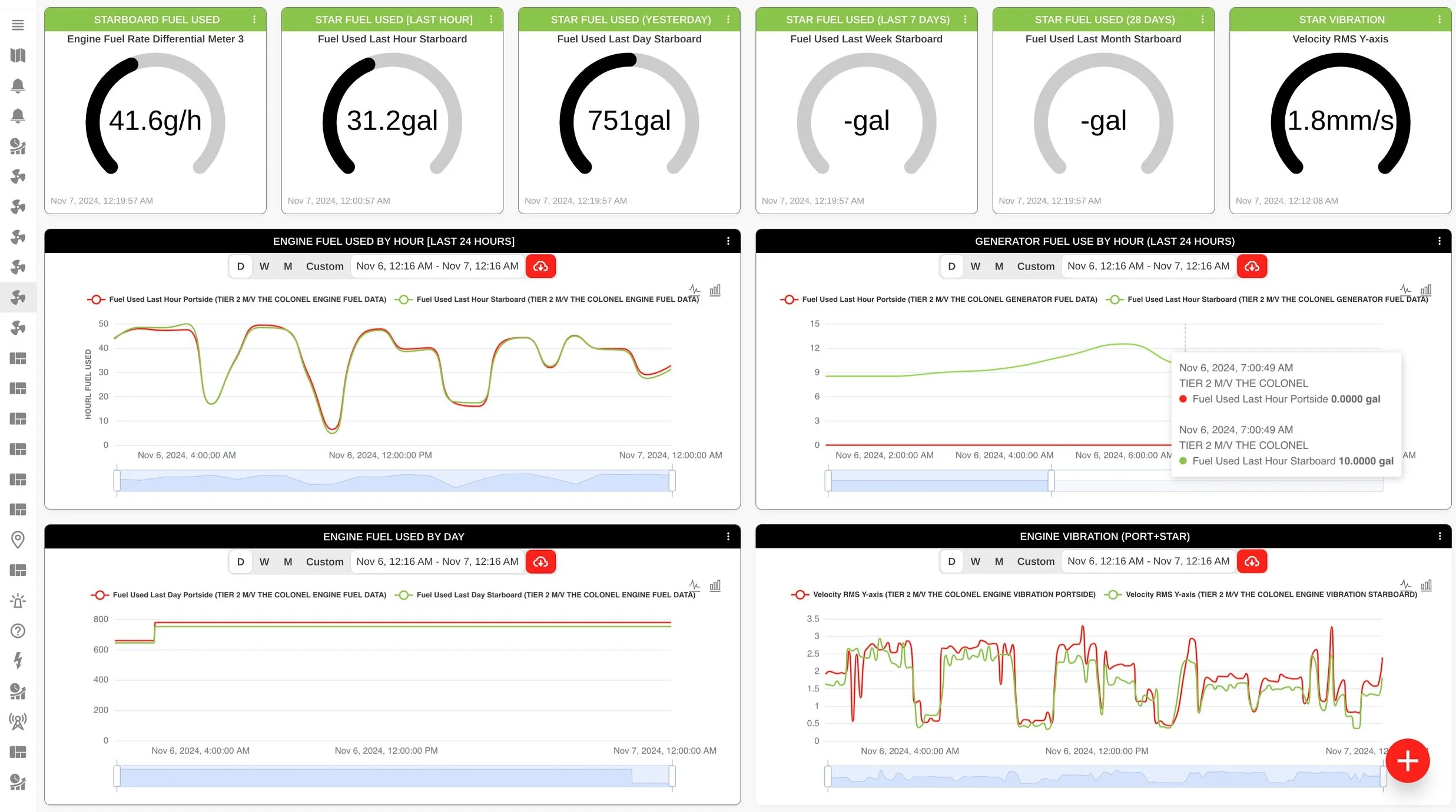

2. Reports That Turn Data into Decisions

Automated 7-day/30-day reports emailed to stakeholders.

Exportable charts and logs for compliance audits or performance reviews.

Custom dashboards to compare equipment health across sites.

3. Plug-and-Play Sensors for Instant Insights

1,000+ pre-configured sensors track temperature, vibration, energy use, pressure, and more.

No coding or IT help needed: Install in 15 minutes and start streaming data.

Works on mobile or stationary equipment (e.g., trucks, turbines, refrigerators).

4. Integration Without Headaches

Connects to 30+ systems like AWS, Azure, Ignition, and PI Historian.

Pulls data from legacy tools or fills gaps with new sensors.

Why pulseCHECKER Wins Over Teams

Guaranteed ROI: 30-day pilot with a money-back promise.

No Industry Limits: Works for HVAC, manufacturing, healthcare, retail, and more.

Scalable: Start with one sensor, expand to thousands.

Zero Training: Dashboards show data in plain English, not engineering jargon.

The Bottom Line: Data Isn’t Just Insight—It’s Control

pulseCHECKER turns fragmented data into actionable power. It’s not just about avoiding fires—it’s about equipping your team with the tools to predict, optimize, and dominate, no matter your industry.